silicone moulding and resin casting

In order to make a casting it was necessary to first create silicone moulds of a positive of the railing elements. These silicone moulds later were used to cast the resin elements. This page documents the process of creating silicone formwork, moulds and resin casts. Robbie and Steve completed most of this section of the model as I was concentrating on other parts of the model.

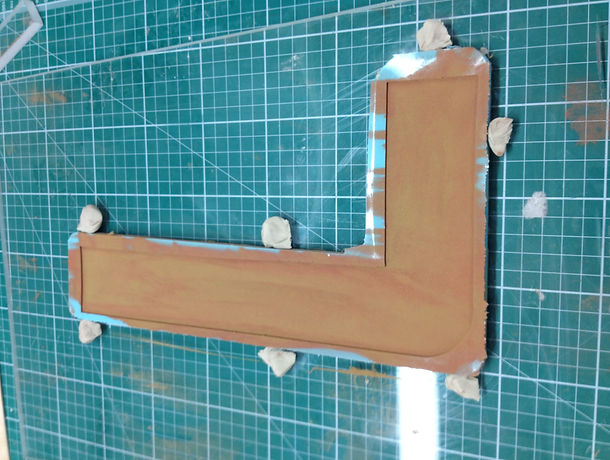

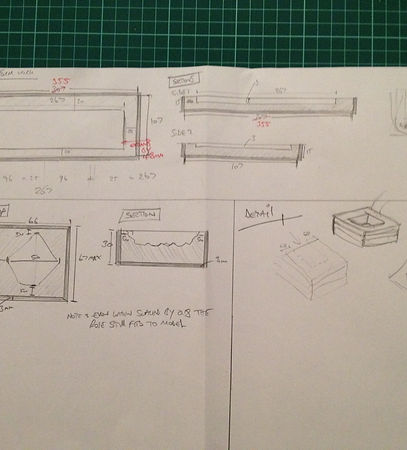

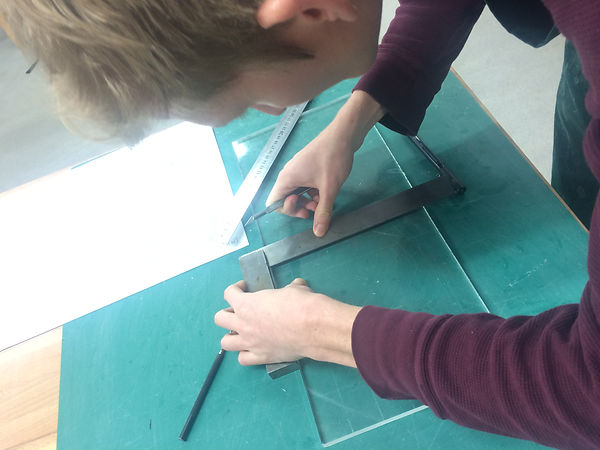

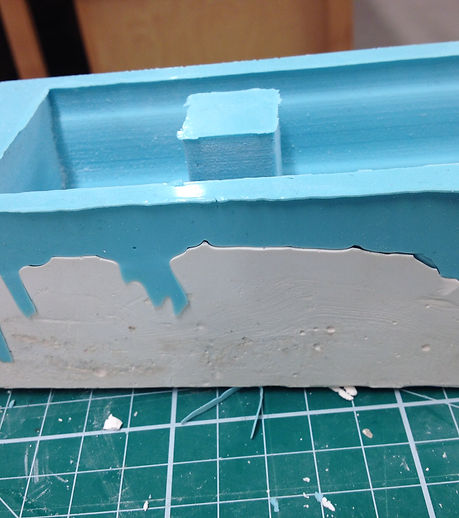

We planned to cast every element of the railing so that it was consistant and true to the real construction of the railing. We used acrylic off cuts to build formwork which held the silicone. The formwork was designed to be dismantlable so that the cast could be extracted from the mould.

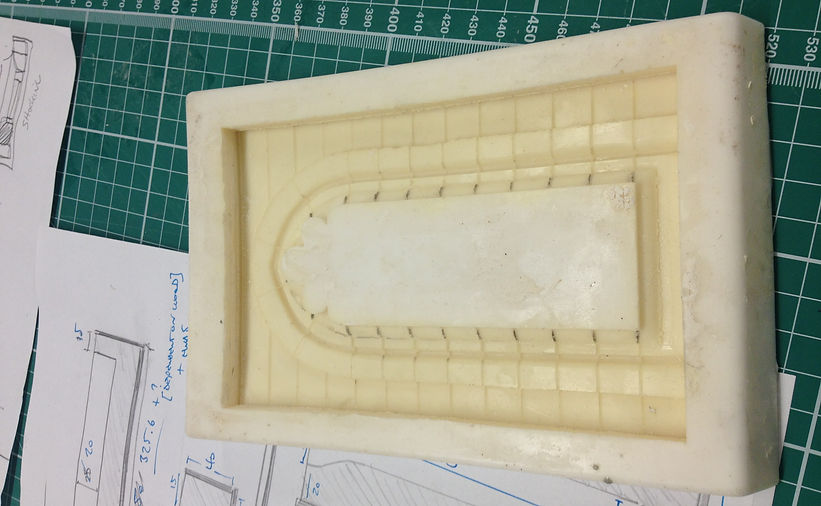

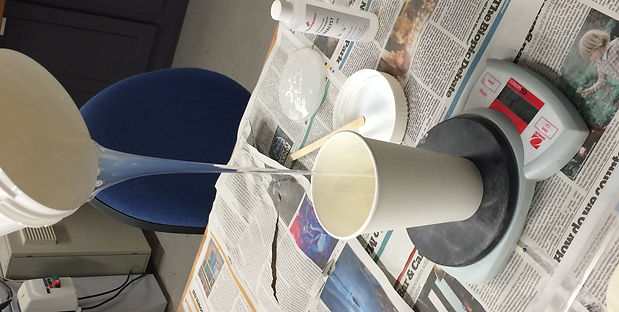

Scott showed us how to pour silicone to minimise the bubbles trapped within the liquid. The silicone is expensive and limited so we decreased the volume of the mould with space fillers and plasticine. We left the mould drying on a vibrating saw bed in an attempt to eliminate the bubbles.

The resin casting technique had not been attempted by any of us before and it was therefore a learning curve of trial and error. Integral to the sucess of the cast was the proportions of resin to metal power and the drying time.

Looking at previously cast models we learnt that the back side does not pick up the metal powder and as a result it looks like plastic. This was a problem because some of our cast elements required a metal looking surface on all faces. Steve tested out an idea of his, sprinkling the power on the top surface. The result was positive and gave it a texture that looked similar to a true metal cast.

We tested different powders and colours to make an informed decision about what looked best in reality with the wood. We decided on a mixture of the copper and brass powder.

Steve came up with to put plaster in the silicone to minimise the quantity of silicone. We also used foam fillers in the casts which allowed us to minimise the use of resin, bringing costs down.

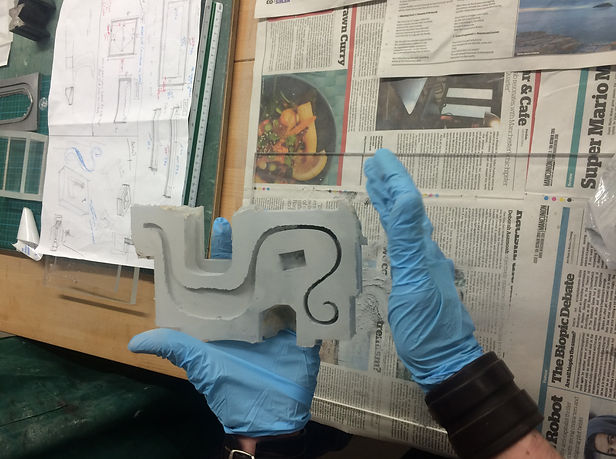

The photo below shows why we used silicone. It provides a good flexibility without tearing. Other moulding materials can be brittle when deformed too far.

The railing element was an important piece that required a presentable face on all sides. Our plan was to create the cast (picture right) and then to sand down the top and create a cast plate which would finish the surface in good condition.