Alginate cast

The plan to replicate the rose detail on the railing was to create an actual cast of the railing. For this we used alginate which is mostly used by dentists to take casts of teeth. It is an ideal moulding material for this task because it sets very quickly and only requires water.

It was my job to go to the library to create the cast. Steve had already made the formwork which would hold the alginate in place.

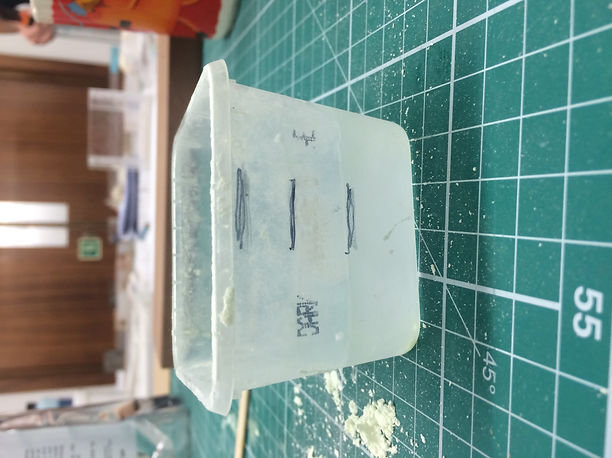

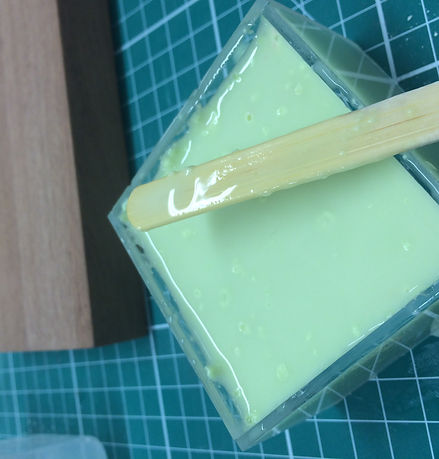

Prior to going, I did some tests with the alginate to get to grips with the desired proportions, consistencies and drying times. I wanted to spend as little time as possible standing on the street doing strange casts to buildings.

The packet said that the alginate could be mixed two parts water, one part alginate powder for a pouring consistency and one part water, one part alginate power for a paste. I first tried two parts water. This did not create a good consistency and the alginate did not set properly.

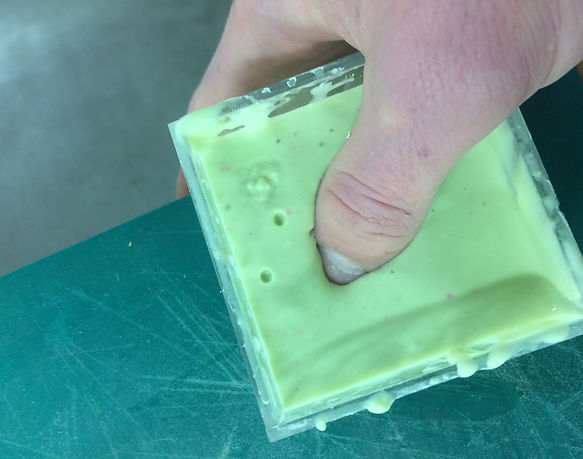

I tried a new batch with one part water one part alginate and the consistency was good and set evenly. I tested this cast on my thumb.

Happy with understanding the proportions I set out to John Rylands to create the cast.

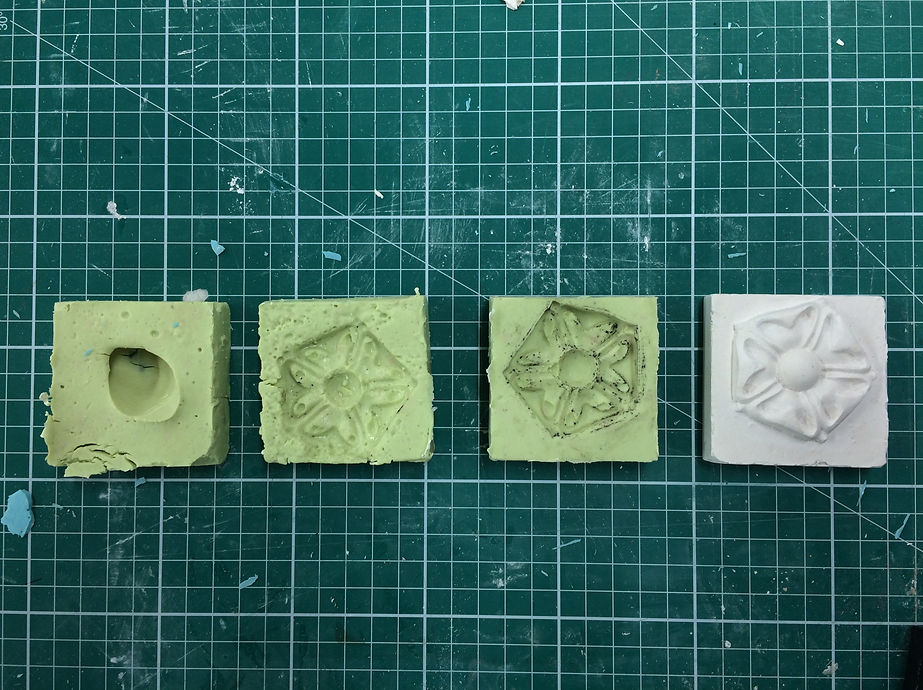

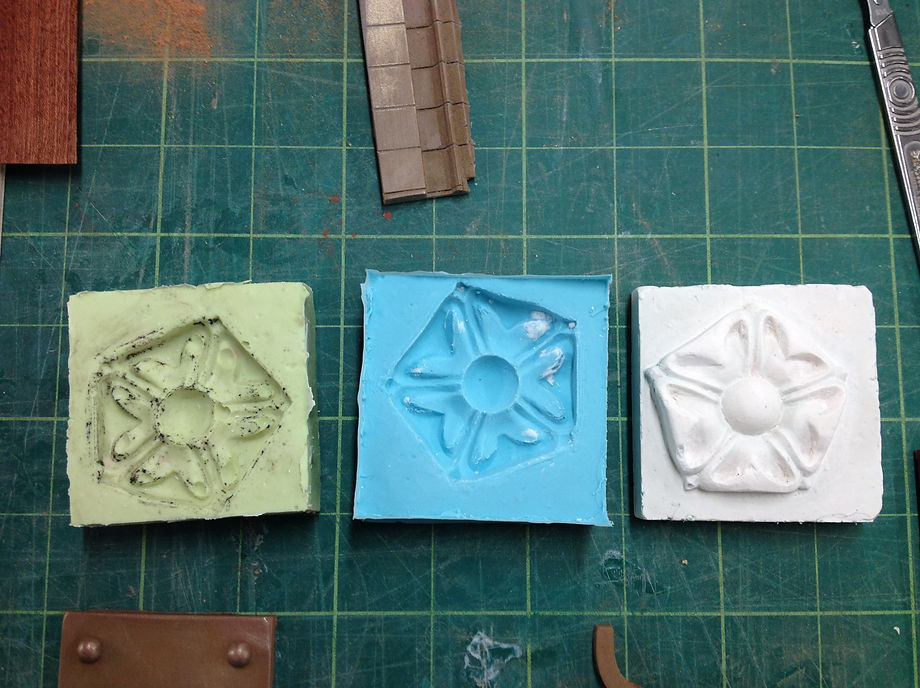

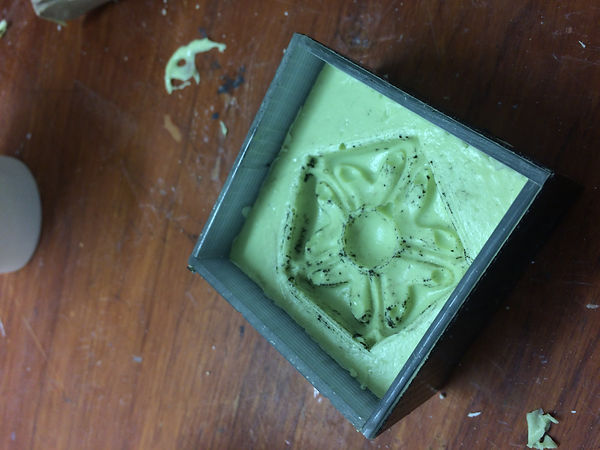

The first mould did not work. Because I had done tests beforehand I knew this was because there was too much water in the mix. I re did the mixture and make a successful mould of the rose. I had to endure lots of strange looks from passers by.

When I returned, Steve made up some plaster and we created a positive cast of the rose. Steve managed to mix the plaster without a single bubble.